Internally fed drum screen is an essential part of wastewater treatment. We produce and export externally fed drum screens. Please contact us for pricing and customizing options.

The internally fed rotating drum screen is used in tannery, poultry, food, paper, and similar industries, especially for the separation of fine waste material that tends to hang, floats, and does not settle.

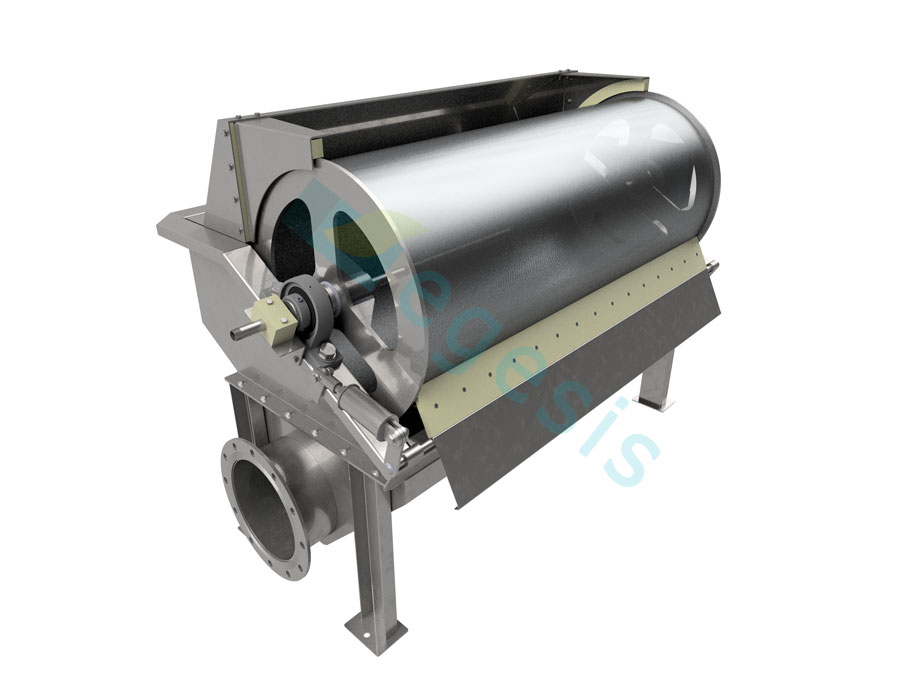

In an internal feed rotating drum screen, the solid and liquid wastes enter the horizontally configured drum through the center then dropped on to the screen. Wastewater is filtered through the screen and the screen surface is cleaned with an automatic washing mechanism equipped with nozzles. Solid wastes are thrown out of the drum with the screw system inside the screen. The treated water passes through the rotating drum and is collected in the reservoir under the equipment and transferred to the following system.

The drum consists of mesh screen or perforated stainless-steel sheet metal, carrier chassis, support bearings, caster and pressurized washing system. Due to its completely closed structure, there is no water splashes. Installation includes a connection to the wastewater inlet, and to an outlet. The washing system needs pressurized treated or freshwater connection.

The drum sieve made of AISI 304 and 316 stainless material. It offers advantage with its low energy cost and 0.5-5 mm fine grid spacing.

Fast Quote!